Operations

- Home

- /

- Operations

- /

- Technology

Technology and Infrastructural Development

Kazneft Petroleum’s Production & Maintenance department is constantly assessing the latest developments in infrastructure and technology to help improve safety, reduce environmental impacts and maximise our production profile.

Over the last three years and in conjunction with leading service providers, a number of initiatives have been introduced which are enhancing the way the refinery operates its facilities and pipelines.

Plant ‘down-time’ due to corrective maintenance and prescriptive equipment inspections can have a significant impact on production and therefore it is essential to minimise both the number of interventions and intrusive vessel and piping inspections. To that end KNP has introduced two discrete corrosion and inspection databases. The software incorporates risk algorithms, helps to evaluate corrosion rates, track anomalies and calculate risk based inspection intervals.

Kazakhstan experiences major ambient temperature swings throughout the year and this can have a major impact on both gas disposal by re-injection and process capacity, particularly during the summer months. Kazneft Petroleum is working closely with General Electric to re-power the three gas re-injection compressors to ensure that capacity is maintained during the summer months. Likewise, by developing and designing improved cooling capacity in the oil splitter overhead condensers, there has been significant improvement in the efficiency of the coolers such that the reduction in throughput capacity during the 2009 summer has been significantly less than previous years.

In summary, technological developments are playing a key role in Kazneft Petroleum’s drive for continuous improvement.

Modernization of Oil Refining Capacities

Increasing the depth of oil refining to a level of at least 85-90%, as well as expanding the range of marketable products by launching the production of high-quality environmentally friendly commercial motor gasoline, aviation and diesel fuels corresponding to the EURO-5 class, the company invested in infrastructural development. In 2020, Kazneft Petroleum has successfully completed the construction of the Combined Unit (Hydrotreatment unit, Gasoline isomerization unit, Gasoline catalytic reformer ) gasoline fractions with a capacity of 893 thousand tons per year.

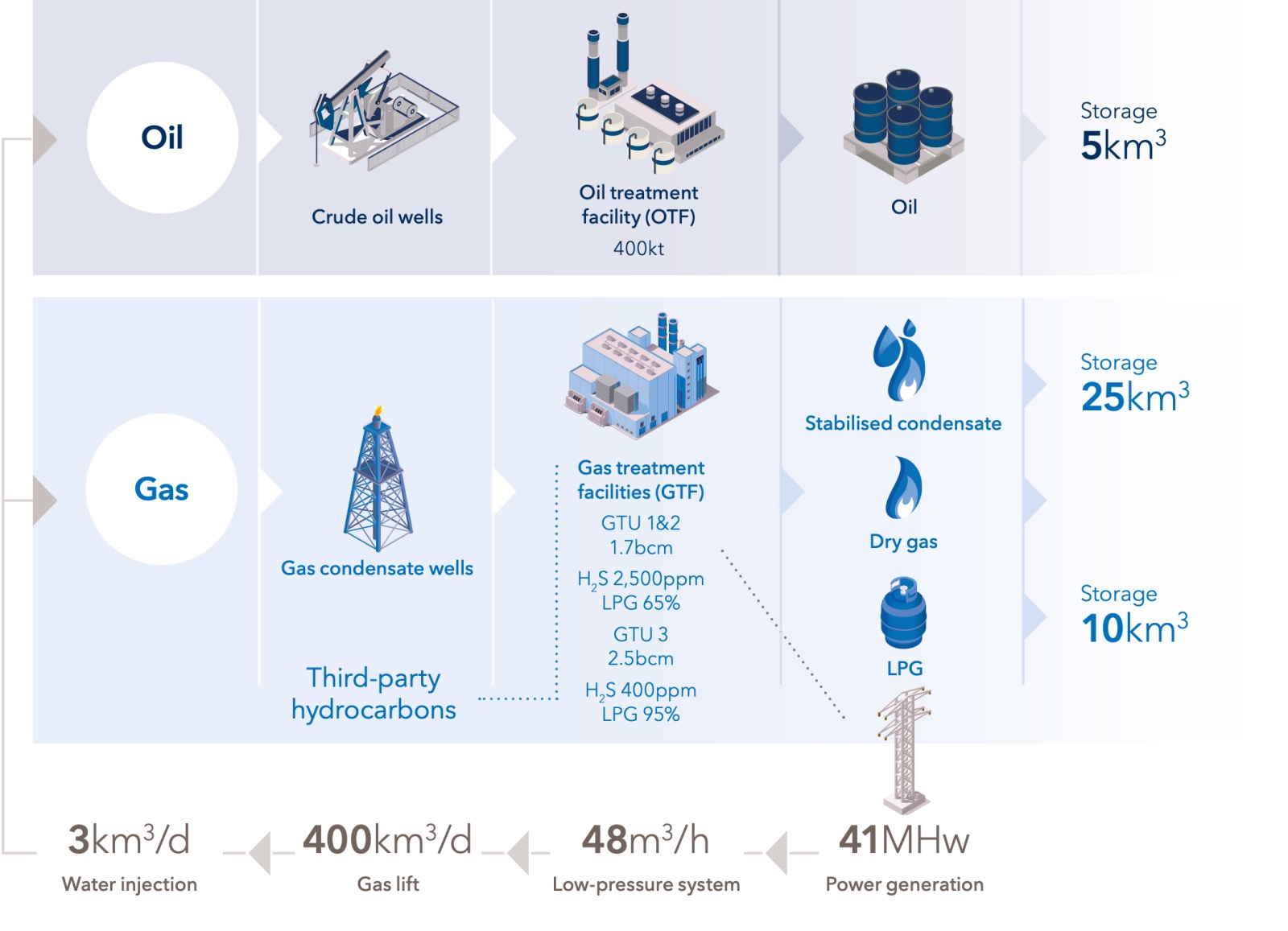

Construction of a plant for the production of liquefied hydrocarbon gases was also completed to increase production of liquefied hydrocarbon gases of grades PBT, BT, PBA with a volume of up to 48 thousand tons per year. Kazneft Petroleum has its own automated rail loading terminal in the city of Karachaganak that receives all domestic crude oil and export condensate produced, and has a capacity of approximately two million tonnes of crude oil and condensate per annum.